EOS Polymer

Modular, reliable and Highly Efficient

Industrial 3D Printing

Polymer 3D Printing: The EOS SLS Process

Are you looking for a compact plastic 3D printer for a quick and cost-efficient start? Or do you need a modular and digitally networked 3D printing platform for industrial series production? EOS offers you 3D printers for plastic parts perfectly tailored to your individual requirements.

At EOS, we can draw on the experience of more than 30 years of additive manufacturing. During this time, we have perfected the Laser Powder Bed Fusion technique and worked out the ideal interaction between 3D printing systems, materials and processes. Our SLS technology stands for manufacturing results that meet a wide range of industrial requirements for dimensional accuracy, surface quality and stability. Take a look at our portfolio of plastic 3D printers and find the perfect match for your application.

EOS’ plastic 3D printers use SLS technology. In Selective Laser Sintering, a laser melts polymer powder and fuses it into a solid 3D printed part. First, a CAD model is created and virtually cut into fine layers. Using this data, the laser beam melts the plastic powder at exactly the specified locations in the powder bed. A new layer of powder is applied and again fused with the underlying layer by laser. In this way, the component is created layer by layer. The SLS process neither requires agents or binders nor tools and is therefore very efficient, flexible and cost-effective.

FORMIGA P 110 FDR

High Detail Resolution

filigree parts and ultra-smooth surfaces to open up new applications.

Your EOS 3D Printer for Plastics: Find the Right Build Volume

EOS offers you flexible and highly productive SLS 3D printing solutions for series production: from user-friendly compact printers to bigger versions for large parts and ultra-fast systems for particularly efficient production.

FORMIGA P100 Velocis

Excellent quality of pieces in the minimum space

The machine is low maintenance and requires very few accessories. Parts are ready for application immediately after unpacking and cleaning. No post processing steps required

EOS P3 Next

Boost productivity by 50%, cut costs by 30%, and achieve double efficiency thanks to 90% machine availability and 80% material reuse

EOS P770

Manufacture of parts up to 1 meter in length

With the currently available selection of 9 plastic materials and 9 material/layer thickness combinations, EOS is a leader in material diversity. Additionally, the EOS Parameter Editor can be used to define custom exposure parameters based on tested initial values.

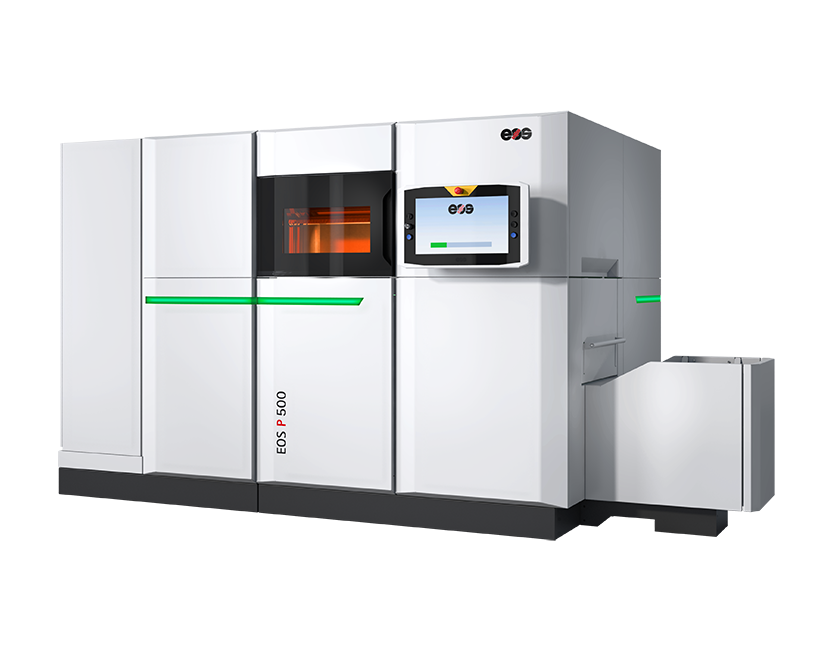

EOS P500

Fast and Economic

The fastest system on the market, it significantly reduces cost per part and offers an easy-to-automate platform with software interfaces for production.The system processes high-performance plastics, allowing for maximum material diversity.

Materials

EOS plastic materials for 3D printing

We offer a wide selection of materials for the production of plastic parts through additive manufacturing processes. This makes it possible to manufacture highly individualized products with first-class quality. We have the following plastic materials for 3D printing Polyamides (PA), Thermoplastic Elastomers (TPE) and Polyarletherketones (PAEK). Our PA 1101 and PA 2200 materials are also available in a carbon-reduced and even neutral version.

PAEK

PAEK materials are high performance plastics with excellent mechanical properties, even at high temperatures. They are flame retardant, extremely resistant to chemicals and especially suitable for the production of high performance molded parts.

PA 11

PA 11, also known as nylon, is a chemically and mechanically heat resistant material, ideal for highly technical applications due to its durability.

PA 12

The white powder of polyamide 12, also known as nylon. Parts made of PA 12 are robust, stable, chemically resistant and versatile.

TPU

Parts made from this white material are extremely resistant to hydrolysis, with high resilience and good tribological properties. The degree of flexibility can be influenced by the part design and the choice of process parameters, and can even vary within the same part.

PA 1101 Climate Neutrality

White, light-transmitting, additively manufactured parts are characterized by high impact strength and elongation at break. They do not splinter even under the highest mechanical loads. Compared to PA 12, they have higher temperature resistance and almost constant mechanical properties over a wide temperature range.

100% quality checked and 0% CO 2 e

PA 2200 Reduced Carbon

The property profile of durable white parts made of PA 2200 is very balanced: these parts are characterized by strength, rigidity and good chemical resistance. They can be biocompatible and certified for contact with food.

Biocompatible material and process. Sustainability is important

100% proven quality and 45% less CO 2e

PA 2241FR

Complies with standards and qualifications: FAR 25.853, AIRBUS directive for plastic parts manufactured in AM.

PA 2210FR

Equipped with a halogen-free chemical flame retardant. Underwriters Laboratories (UL) has issued a Blue Card (equivalent to the well-known Yellow Card) specifically dedicated to 3D printing materials to PA 2210 FR

PA 2220 HighReuse

EOS PA 2220 HighReuse is a highly efficient polyamide 12 material serving a broad variety of applications thanks to its balanced property profile.

PA 950 HD

The material has exceptionally high reusability to increase production efficiency. Parts produced from PA 950 HD exhibit superior stability and surface finish.

Consult with an expert in Additive Manufacturing

Read more about GDPR compliance

Responsible: RMS

Purpose: Collection of personal data to be able to attend to your request

Legitimation: Consent of the interested party

Recipients: No data will be transferred to third parties, except legal obligation

Rights: Access, rectify or delete the data, as well as other rights, as explained in the additional information.

Images provided by EOS, LITHOZ y RMS